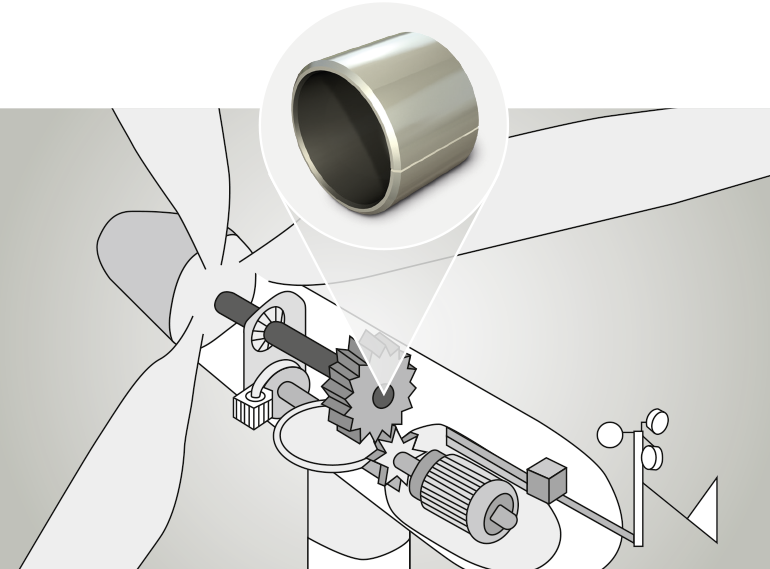

Gearbox rotor shaft in wind turbine systems

Sector: power engineering

Product used

Function

Most wind turbine systems have a horizontally-mounted 3-blade rotor. The wind causes the rotor blades to rotate. The mechanical rotary motion is transferred from the rotor hub to the rotor shaft. Thelow speeds of the rotor are converted at a ratio of 1:25 by a gearbox for generator operation. The rotor shaft is installed in the hollow shaft of the gearbox in the input stage. The rotor shaft and hollow shaft are connected on one side and rotate synchronously. The rotor shaft twists as a result of the strong alternating stresses. This leads to micro-movements on the guide parts. Such strained contact points are usually subject to tribo-chemical corrosion.

Bearing with PERMAGLIDE® P180 plain bearing bushes

With a maintenance-free PERMAGLIDE P180 plain bearing, tribo-chemical corrosion is prevented and the guide quality of the bearing position is improved. The negative impact from stick-slip is minimised thanks to the low friction coefficient of PERMAGLIDE P180 plain bearings.

Advantage: reliable function of the bearing with PERMAGLIDE® P180 plain bearings

- Maintenance-free

- Protected from tribo-chemical corrosion

- Low operating bearing clearance

- Low level of wear, even with alternating stresses

- Low friction coefficient

Download

Information about the products

Contact