KS P180 lead-free plain bearing material – highly resilient, resistant, suitable for universal use

P180 … Highly resilient and resistant – the sustainable and lead-free P1 material of the future

P180 is a lead-free high-performance material with outstanding tribological performance. It is designed for maintenance-free applications under dry-running conditions. In addition, it can be used in both grease- and liquid-lubricated systems. P180 is a further development of the tried and tested P14 material with improved resilience and wear resistance whether in dry or lubricated applications. The material can also be used in tribological systems that were previously only operated with materials containing lead, such as P10.

IMPORTANT: The material P180 is RoHS 2 compliant!

Note

In comparable applications, the material P180 has proven itself.

Material manufacture

The solid lubricant mass is produced in a specially adapted mixing process.

In a parallel, continuous sintering operation, bronze powder is sintered onto the steel back as a sliding layer. This produces a sliding layer with a thickness of 0.2 mm to 0.35 mm and a pore volume of approx. 30%.

Next, the cavities are filled with solid lubricant by means of impregnating rollers.

This process step is controlled in such a way that a running-in layer of solid lubricant up to max. 0.03 mm thick is produced above the

sliding layer. In further thermal treatments, the characteristic properties of the material system are adjusted, and the required thickness tolerances of the composite material are produced using controlled roller pairs.

Note

The material P180 is suitable as a substitute for materials containing lead and in some cases can exceed their performance limits.

Plain bearing production

Sliding elements in a great variety of designs are produced from P180 in cutting,

stamping and shaping processes.

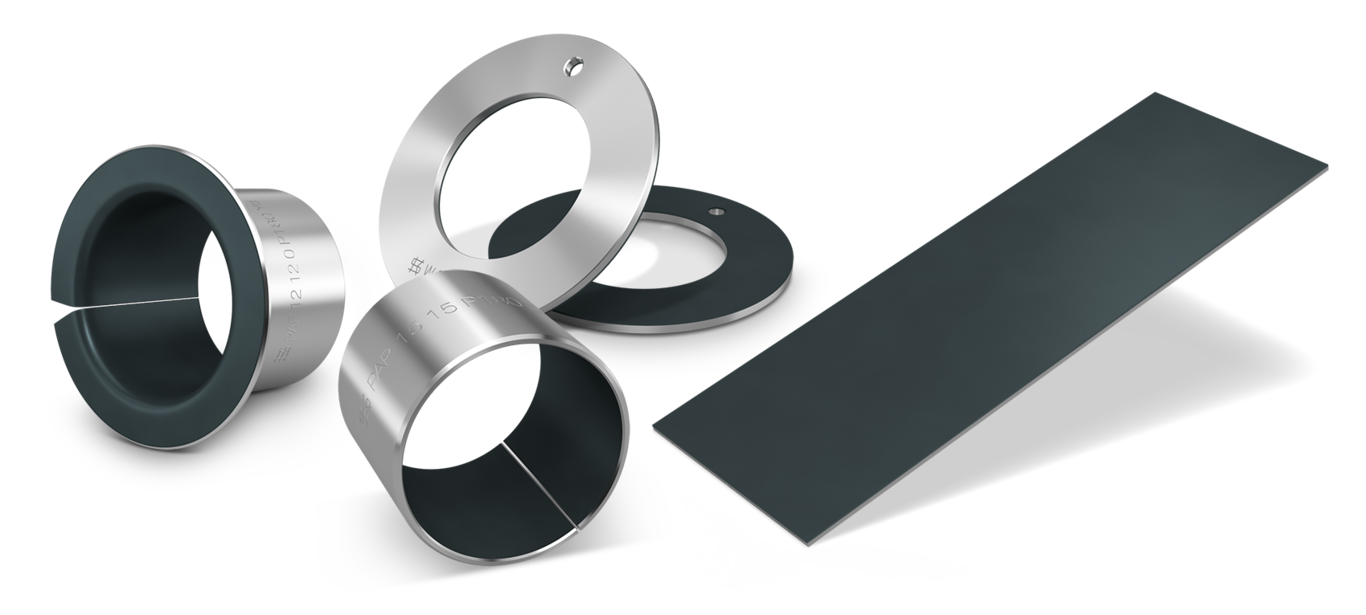

Standard designs are:

- Cylindrical bushes

- Flange bushes

- Thrust washers

- Strips

In a final step, plain bearings manufactured from P180 undergo anti-corrosion treatment on the bearing back, end faces and striking faces.

Standard version: Tin

Layer thickness: approx. 0.002 mm

Note: Tin is used as temporary corrosion protection and an assembly aid.

Characteristics of P180

- Lead-free

- Compliant with Directive 2011/65/EU (RoHS II)

- Very low stick-slip tendency

- Extremely resilient, especially with edge wear

- Low and constant friction value

- Very good wear resistance in dry running and wet running

- Universally applicable: suitable for rotary, oscillating and axial applications

- Excellent chemical resistance

- High resistance to erosion

- Largely resistant to swelling

- Compatible with all common dry-running steel shafts

Preferred areas of application

- Operation under dry and lubricated running conditions, where lead-free is required

- Rotating or oscillating movements up to a velocity of 2 m/s

- Linear movements

- Temperature range -200°C to 280°C

Hydrodynamic operation

Use in hydrodynamic conditions is possible without problems up to a sliding speed of 10 m/s. The material has a high resistance to erosion and cavitation. Motorservice offers the calculation of hydrodynamic operating states as a service.