03/07/2024 | Press release

Wear on plain bearings – Permaglide® P1 materials compared

Are you familiar with our technical know-how on plain bearings? For example:

Wear on plain bearings – Permaglide® P1 materials compared

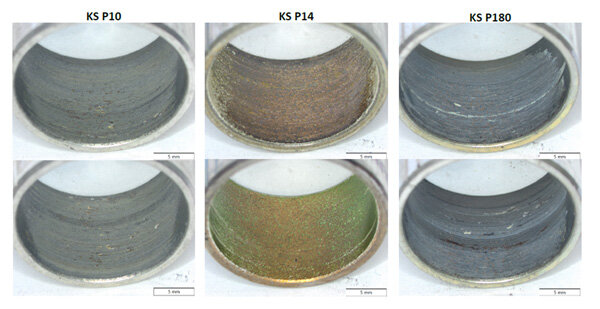

Material wear is a complex process that is influenced by many parameters – in addition to purely mechanical, dynamic and tribological parameters such as lubrication and friction conditions, the condition of the interacting sliding partner, i.e. its material, hardness and roughness, has a significant impact. A preference for a material under the respective usage conditions can be derived using tests under standardised conditions with one parameter being varied.

P180 all-rounder and test winner

The new material Permaglide® P180 is characterised by the lowest wear amongst the materials tested and impresses both in dry running and in lubricated applications. This backs up the P180 material’s credentials as a new universal material.

Our service information provides you with an overview of the wear of the sliding layer on P10, P14 and P180 plain bearings according to the various plain bearing tests.Download: SI 2079 - Wear on plain bearings – Permaglide® P1 materials compared

Here you can find out more about P180, such as the advantages, features and properties of the new material.